Specialist Machining & Machine Shop Capabilities for Custom Industrial Parts

Advanced machining and machine shop solutions are fundamental to the creation of custom industrial components. These services support diverse industries, ensuring exactness and quality in every piece. Proficient machinists apply advanced processes to meet specific project needs. Understanding the nuances of these processes can substantially influence product results. As industries develop, so too do the technologies that drive these solutions. What does this mean for future manufacturing methodologies?

Leading Advantages of Custom Machined Parts Across Multiple Industries

Though mass-produced components have their place, custom machined parts deliver significant advantages that can substantially enhance multiple industries. One of the primary benefits is precision; custom machining allows for exact specifications suited to specific applications, providing superior performance. This level of accuracy reduces the likelihood of errors and lessens the need for adjustments during assembly.

In addition, custom machined parts provide greater material versatility, enabling engineers to select suitable materials according to the environmental conditions and performance requirements. This adaptability can significantly increase the longevity and durability of components.

Additionally, valuable resource custom solutions can foster innovation, as one-of-a-kind designs can result in improved functionality and efficiency. In fields such as aerospace, automotive, and medical, where performance is essential, these advantages become imperative. Eventually, the ability to produce specialized parts enhances improved productivity and competitiveness in numerous industries.

What Exactly Is Professional Machining and Machine Shop Services?

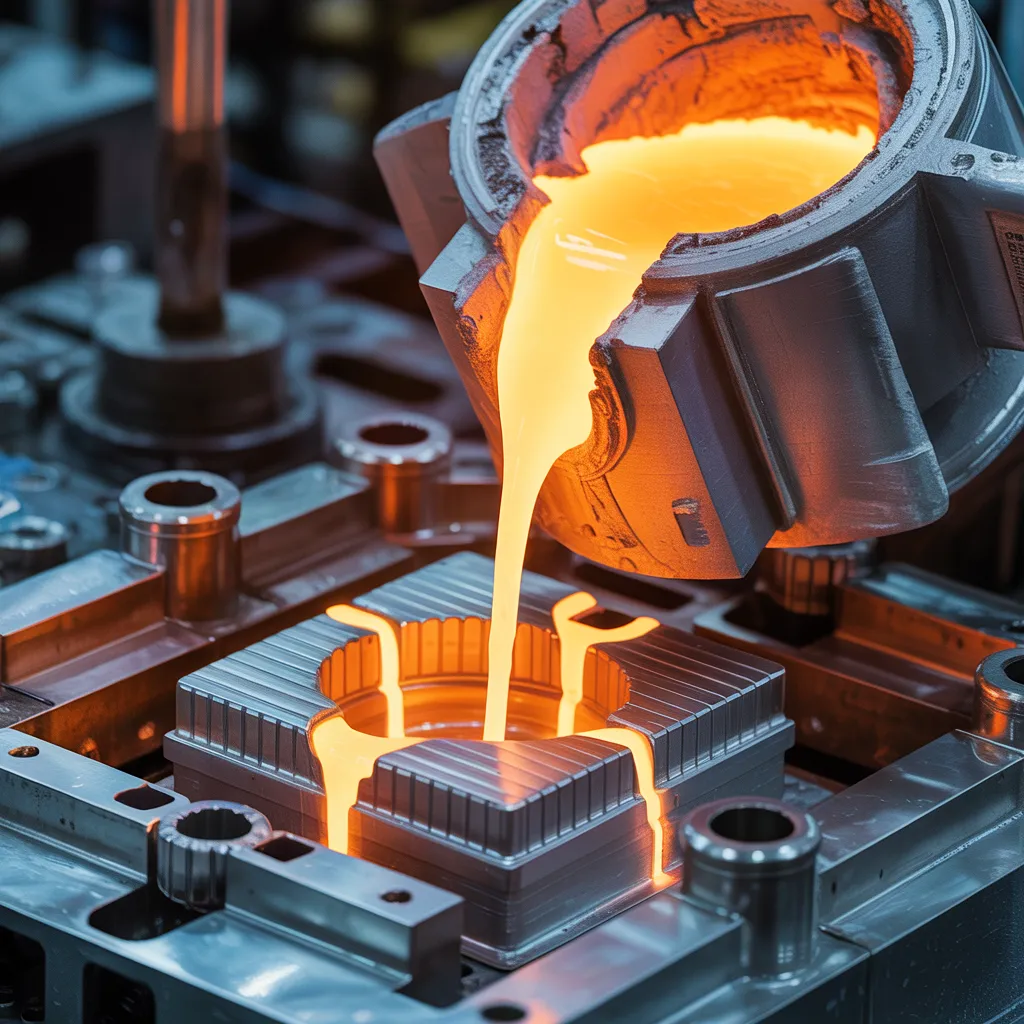

Professional machining and machine shop services offer an extensive selection of services customized to fulfill the needs of multiple industries. These offerings comprise an array of processes, including precision machining, CNC machining, milling, turning, and grinding, allowing for the manufacturing of complex and highly detailed components. Skilled machinists employ cutting-edge technology and equipment to provide precision and productivity in fabricating custom parts.

In addition, expert machining services often include consultation on design, prototyping, and quality assurance, guaranteeing that the final products satisfy stringent specifications and industry standards. With capabilities to work with a diverse selection of materials, from metals to plastics, these machine shop solutions cater to sectors such as aerospace, automotive, medical, and energy. By leveraging expertise in machining techniques and industry knowledge, these service providers help organizations reach their production goals while maintaining superior outcomes.

Choosing the Right Machining Partner: Key Considerations to Consider

When selecting the ideal machining partner, what vital factors should be factored in? Initially, the partner's experience and expertise in the pertinent industry must be examined. This includes examining their expertise in specific materials and processes associated with the project. Furthermore, the machining capabilities should align with project requirements, such as precision, complexity, and volume.

A further significant aspect is the quality assurance procedures in place. A reputable partner will have strong quality control measures to certify that all parts meet industry standards. Customer service and communication are equally important, as a collaborative relationship can support more effective project execution.

Last but not least, it's important to consider cost-effectiveness, weighing quality with budget limitations. A detailed analysis of potential partners based on these criteria can lead to a productive collaboration, in the end delivering high-quality custom parts that meet or exceed expectations.

How Innovative Technologies Are Altering Machining Services

Innovations in technology are substantially transforming machining services, increasing productivity and precision in the production of custom parts. The integration of computer numerical control (CNC) machines enables automated and highly precise operations, reducing human error and increasing output consistency. Additionally, the adoption of additive manufacturing technologies enables complex geometries to be created with minimal waste, thereby promoting sustainability.

Software developments, like CAD and CAM, allow for better design and simulation processes, enabling engineers to conceptualize and test components ahead of physical production. Additionally, real-time data analytics and IoT connectivity strengthen monitoring and maintenance, leading to reduced downtime and optimized production schedules.

Such technological advancements not only optimize work processes but also help machine shops to respond more swiftly to market pressures. As a result, companies can offer bespoke solutions while sustaining competitive pricing and shorter lead times, ultimately changing the landscape of machining services.

Navigating the Process: From Proof of Concept to High-Volume Production

Though shifting from prototype to comprehensive production can be challenging, a clearly defined process can facilitate this journey. At the outset, clear specifications and design documentation are crucial, confirming that all stakeholders grasp the project requirements. After this, a detailed evaluation of production capabilities, materials, and technology must be conducted to identify the most effective methods.

Subsequently, a pilot run is frequently implemented to assess the manufacturing process, facilitating the identification of potential issues before full-scale production begins. During this phase, collaboration between engineers and production teams aids in to refine techniques for efficiency and quality assurance.

Upon successful pilot validation, increasing production calls for strategic planning, including management of timelines and allocation of resources. Constant monitoring and feedback processes will help maintain quality and adapt to any unpredicted difficulties. Through adherence to these steps, enterprises can effectively progress from prototype phase to full production scale, guaranteeing both product integrity and efficiency.

Frequently Asked Questions

Which Material Options Are Available for Custom Machined Parts?

Numerous materials can be used for custom machined parts, including aluminum, steel, titanium, brass, and plastics. The option depends on considerations for example strength, weight, corrosion resistance, and the specific application demands.

How Can I Guarantee Design Precision in My Specifications?

To secure design accuracy in specifications, one should utilize precise measurement tools, create in-depth drawings, engage in rigorous reviews, and collaborate with experienced engineers. Regular feedback and iterative prototyping can also improve overall precision and reliability.

What Is the Typical Turnaround Time for Custom Machining Projects?

Average turnaround time for custom machining projects differs, generally ranging from several days to several weeks. Factors determining this include complexity of the project, availability of materials, and the shop's work capacity, impacting overall production timeframes.

Is There a Minimum Order Quantity for Custom Machined Parts?

Usually, custom machined parts do have minimum order quantities, which can vary relative to the sophistication, material, and machining processes involved. These stipulations establish optimized production and cost-effectiveness for both the manufacturer and the client.

How Do I Properly Maintain My Custom Machined Parts After Production?

For maintaining custom machined parts after production, periodic cleaning, lubrication, and inspection for wear are necessary. Moreover, storing parts in a controlled environment can stop corrosion and extend their operational lifespan notably.