A Complete Guide to Aluminum Castings: Types, Processes, and Their Applications

Aluminum castings play an important role in numerous industries, providing lightweight yet strong components. Multiple casting processes, such as sand and die casting, address specific production needs. Understanding these methods and their applications is crucial for maximizing material use. As the demand for energy-efficient solutions grows, the importance of aluminum castings continues to increase. What factors should one consider when choosing the right casting for a project?

Understanding Aluminum Castings and Their Importance

Aluminum castings are essential components in various industries, serving as the backbone of numerous products and applications. These castings are produced by pouring molten aluminum into molds, enabling it to solidify and form. They are valued for their lightweight, high strength, and corrosion resistance, making them ideal for automotive, aerospace, and consumer electronics industries.

The importance of aluminum castings stems from their ability to provide complex shapes and designs that would be challenging or unfeasible to achieve with other manufacturing techniques. Their versatility means they can be adapted to meet specific performance criteria, enhancing the overall functionality of products. Moreover, aluminum castings support energy efficiency, as lighter components can bring about reduced fuel consumption in vehicles and aircraft. Overall, the significance of aluminum castings is critically important, as they play a essential role in modern manufacturing and technology.

What Is the Manufacturing Process for Aluminum Castings?

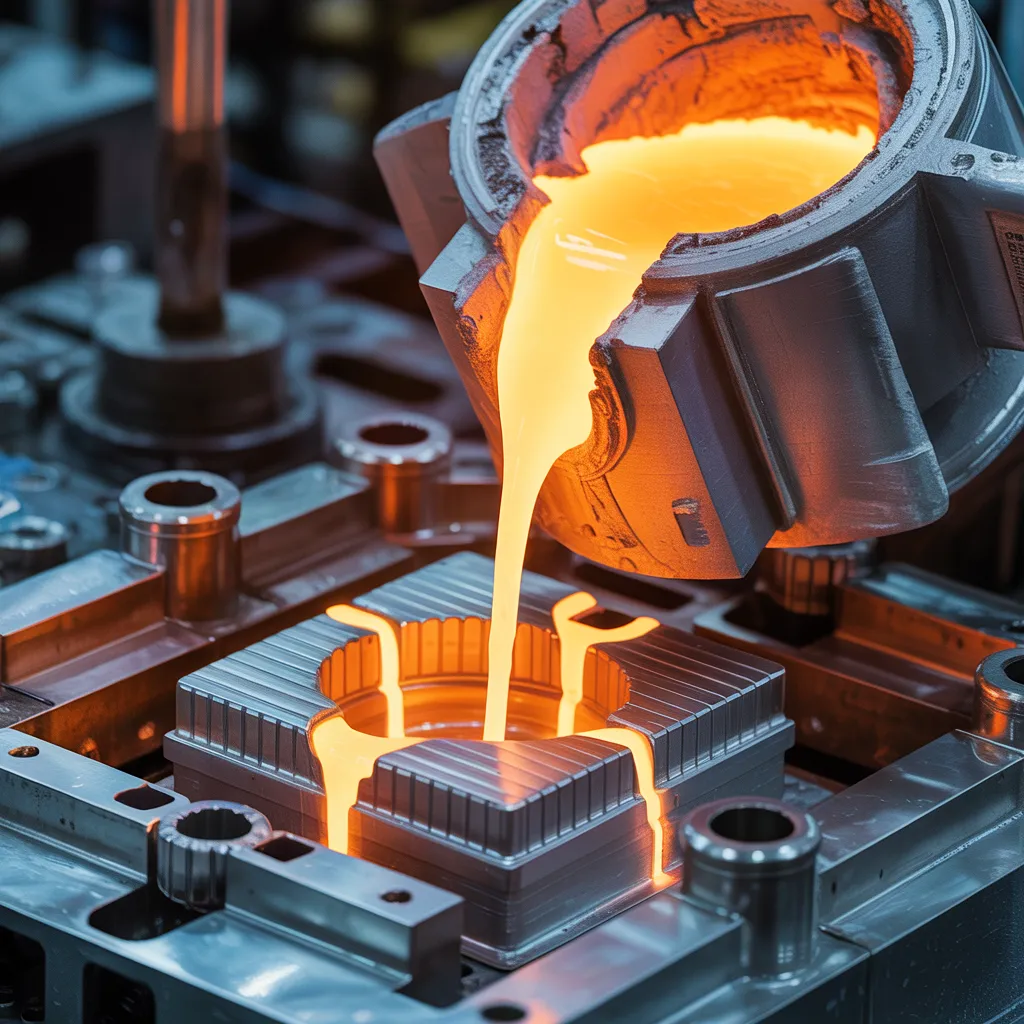

Aluminum casting creation encompasses several key steps that transform raw materials into precision-engineered components. At the outset, high-quality aluminum ingots or scrap metal are melted in a furnace, reaching temperatures between 1,200°F to 1,400°F. Once molten, the aluminum is often treated to remove contaminants, ensuring outstanding casting quality.

Following this, the liquid aluminum is introduced into a ready-made mold, which can be created from different materials relative to the desired casting method. After the aluminum flows into the mold, it is given time to cool and solidify, adopting the shape of the mold.

When cooled, the casting is removed from the mold and undergoes finishing processes, such as machining, to achieve the needed tolerances and surface finishes. In conclusion, the cast component is checked for quality assurance, ensuring it meets industry standards before being delivered for use in diverse applications.

Common Aluminum Casting Procedures: Sand, Die, and More

Various processes are utilized in the aluminum casting industry to achieve desired shapes and properties. Among the most popular methods are sand casting, known for its versatility and cost-effectiveness, and die casting, which offers high precision and efficiency. Every method possesses distinct advantages, rendering them appropriate for various manufacturing applications.

Sand Casting Procedure

Although multiple casting approaches exist, sand casting stays one of the most popular processes in aluminum manufacturing thanks to its adaptability and cost-effectiveness. This process involves creating a mold from sand, which is then filled with molten aluminum. The sand permits intricate designs and shapes, making it appropriate for both large and small components. The process starts with the preparation of a sand mixture, followed by the formation of the mold around a pattern. Once the aluminum is dispensed and solidified, the mold is broken to remove the casting. Sand casting is particularly advantageous for low to medium production runs, as it requires less initial investment compared to other processes, while still delivering high-quality results.

Die Casting Processes

Die casting methods are a leading method for manufacturing aluminum components, particularly when intricate designs and high precision are needed. This process consists of forcing molten aluminum into a mold cavity under high pressure, providing a perfect replication of the mold's details. There are two principal types of die casting: hot chamber and cold chamber. Hot chamber die casting is ideal for low-melting-point alloys, while cold chamber is appropriate for higher melting-point materials. Both methods deliver excellent dimensional accuracy and surface finish, making them appropriate for various applications, including automotive parts, consumer electronics, and industrial machinery. In summary, die casting techniques provide a reliable solution for manufacturers seeking quality and efficiency in aluminum component production.

The Reasons to Choose Aluminum Castings?

When exploring manufacturing options, many industries gravitate towards aluminum castings because of their exceptional combination of strength, lightweight properties, and corrosion resistance. The versatility of aluminum allows it to be easily molded into complex shapes, which makes it ideal for a variety of applications. Furthermore, aluminum castings can be manufactured with high precision, which is vital for meeting rigorous quality standards in modern manufacturing.

Moreover, the thermal conductivity of aluminum enhances its performance in heat-related applications. Its ability to resist oxidation and maintain structural integrity over time makes it notably appealing for outdoor and harsh environments. Moreover, aluminum castings offer outstanding recyclability, enabling sustainable manufacturing practices. The overall cost-effectiveness, coupled with the reduced weight of aluminum components, leads to lower transportation costs and energy savings in end products. These advantages position aluminum castings as a preferred choice across multiple sectors, including automotive, aerospace, and consumer goods.

Where Can Aluminum Castings Be Found?

Aluminum castings find extensive application across numerous industries due to their beneficial characteristics. In the complete article automotive sector, they are regularly employed for engine blocks, transmission cases, and structural components, leading to weight reduction and better fuel efficiency. The aerospace industry utilizes aluminum castings for aircraft components, where the strength-to-weight ratio is critical.

Moreover, the electronics industry employs aluminum castings for housings and heat sinks, taking advantage of their outstanding thermal conductivity. In the construction sector, they are employed for architectural elements and structural supports, boosting both durability and visual appeal.

Furthermore, the marine industry utilizes aluminum castings for boat components, providing resistance to corrosion. Consumer products, such as cookware and appliances, also employ aluminum castings for their lightweight and efficient heat distribution. All in all, aluminum castings are crucial to diverse applications, highlighting their versatility and utility in modern manufacturing.

How to Select the Right Aluminum Casting for Your Requirements

How can one determine the most fitting aluminum casting for certain applications? The decision process initiates with assessing the application's criteria, including structural attributes, thermal resistance, and weight requirements. Grasping the operating environment is critical; for illustration, exposure to harsh chemicals may require a certain alloy.

Subsequently, the fabrication technique should be evaluated. Sand casting is well-suited for complex shapes, while die casting offers superior accuracy for large-scale manufacturing. Additionally, budget constraints and lead times can affect the selection between these methods.

The target purpose likewise serves a vital function; automotive components may require different properties than aerospace parts. Speaking with a foundry specialist may offer helpful guidance on the optimal choices accessible. Ultimately, a thorough assessment of these factors guarantees the selection of an aluminum casting that meets both performance and economic needs.

Common Questions

What Are the Environmental Consequences of Aluminum Casting Production?

The process of aluminum casting production generates noteworthy environmental impacts, including waste generation, greenhouse gas emissions, and energy consumption. Additionally, the extraction of bauxite for aluminum production may lead to the destruction of habitats and degradation of soil. Sustainable approaches are necessary.

What Are the Differences Between Aluminum and Steel Castings?

Castings made from aluminum are typically lighter, resistant to corrosion, and provide superior thermal conductivity compared to steel castings. However, steel castings typically provide superior strength and durability, making them preferable in applications requiring high strength and load-bearing capabilities.

Is It Possible to Recycle Aluminum Castings?

Indeed, aluminum castings offer efficient recyclability. The recycling procedure sustains material properties, cutting down on energy needs and environmental consequences. These properties render aluminum castings an environmentally responsible selection in numerous industries, fostering circular economic models.

What Are the Common Defects Found in Aluminum Castings?

Standard defects in aluminum castings include porosity, shrinkage, inclusions, as well as surface imperfections. These defects can occur due to inadequate melting practices, faulty mold design, or cooling rate variations, compromising the quality and performance of the final product.

What Are the Steps to Maintain Aluminum Cast Products?

To care for aluminum cast products, you should regularly clean them with a mild detergent, avoid abrasive materials, look for signs of corrosion, apply protective finishes, and store them in a climate-controlled environment to prevent damage.